Eddy Current Sensor Applications

Kaman specializes in inductive, eddy current technology. Our sensors provide non-contact indication of linear position/displacement by outputting an analog voltage, or, in some cases, a current that is proportional to the distance between the sensor face and the target being sensed. Eddy current technology requires an electrically conductive target. It does not need to be […]

eddy current sensor applications. An eddy current is a current set up in a conductor in response to a changing magnetic field. They flow in closed loops in a plane perpendicular to the magnetic field. By Lenz law, the current swirls in such a way as to create a magnetic field opposing the change; for this to occur in a conductor, electrons swirl in a plane perpendicular to the. Vacuum applications have certain considerations when using eddy-current sensors. Learn more from our technical library.. Eddy-Current Sensor TechNote LT02-0021.. The epoxy in the probes has been specifically tested for vacuum applications requiring low outgassing. Probe cabling uses a PTFE jacket which is highly stable and produces very. Eddy current sensors detect the distance or the change to metal objects without contact, dynamically and extremely accurately. The TX electronics which are specially adapted to the respective sensor calculate an analogue output signal proportional to the distance. In addition, there is a USB and CAN interface for reading the data.

The sensors are resistant to dirt, pressure and extreme temperatures, it's these features that make eddy current senors one of the best performing sensors in extreme environments. With a maximum frequency response of 100kHz (-3dB) the sensors can operate at high speed in oscillation and vibration applications. While the eddy current sensor’s operating principles are in line with Faraday’s Laws, it’s the eddy currents’. Applications and Usage . The high cut-off frequency of eddy-current sensors enables metrological detection of distance values even in fast processes, such as machine lathes and crank shafts, and IP67 protection ensures they. Inductive sensors (eddy current) from Micro-Epsilon are often used in applications where harsh ambient conditions are present and where maximum precision is required. Immunity to dirt, pressure and extreme temperature are distinctive features.

Eddy currents (also called Foucault's currents) are loops of electrical current induced within conductors by a changing magnetic field in the conductor according to Faraday's law of induction.Eddy currents flow in closed loops within conductors, in planes perpendicular to the magnetic field. They can be induced within nearby stationary conductors by a time-varying magnetic field created by an. Eddy-current sensors provide high resolution measurement for even the dirtiest environments. These advantages have made eddy-current sensors indispensable for many machine builders, production managers, and precision metrology applications. Non-contact, nanometer resolution, high-speed applications are what we thrive on. History. Eddy current testing (ECT) as a technique for testing finds its roots in electromagnetism. Eddy currents were first observed by François Arago in 1824, but French physicist Léon Foucault is credited with discovering them in 1855. ECT began largely as a result of the English scientist Michael Faraday's discovery of electromagnetic induction in 1831.

Eddy Current Sensors. Inductive Proximity Sensors using the eddy current principle are perfect for applications in harsh environments due to their high insensitivity to oil, dirt, dust, moisture and interference fields. We are specialists in the fields of LVDT displacement sensors (up to 1000 mm displacement) and eddy current sensors (up to 50 mm displacement), as well as measuring amplifiers and sensors in the field of displacement/position measuring technology. Eddy Current Sensors and the Industrial Internet of Things.. Inductive eddy current sensors operate by generating a high frequency electro-magnetic field about the sensor coil which induces eddy currents in a target material. A conductive target is required, but a ground connection to the measuring system is not necessary.. applications.

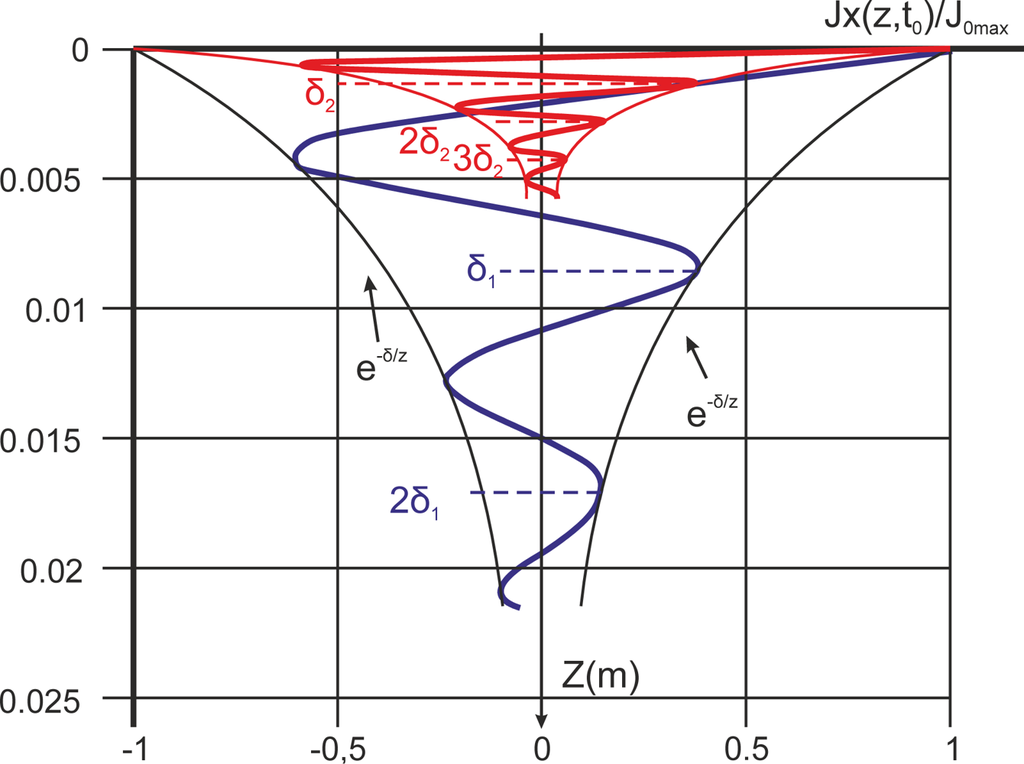

The eddy current sensor needs to be optimized for carbon materials. Different sensor types, such as absolute, differential and compensated sensors, can be used for single sensor probing. The single sensor configuration is a directional sensor with a high spatial resolution due to its high-focusing point-spread function (PSF) [ 8 ] [ 9 ]. Furthermore eddy current sensors are perfectly suited for the observation of dynamic events. Eddy current sensors of the TX-Series stand out with an excellent dynamic range >100 kSa/s and resolutions in the sub-micron range. With this premise the eddy current sensor is suitable for general motion analysis and in automotive applications. Applications in the railway domain 18 IL Eddy current sensor Magnetic sensor I h h Magneec material Conductive material Fig. 1. Field pattern comparison between an eddy current sensor and a magnetic sensor, and curves of the magnetic circuit reluctance. conductivity, the field only penetrates skin deep [3].

eddy current proximity sensor Formula. The target material must be at least three times thicker than the effective depth of the eddy currents to make the transducer successful because the transducer assumes that the eddy currents are localized near the surface of a semi-infinite solid and the actual eddy current amplitude decreases quadratically with distance.